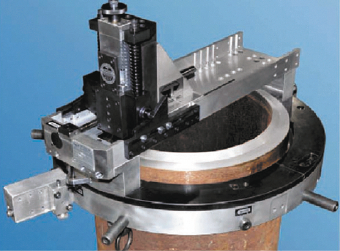

With strong bearing two and a half ring through a connecting bolt are connected into a ring rail,

through the fixed ring card block centering and clamping, through the high power motor driven

tool holder fixed on the rotating ring pipe cutting and beveling.

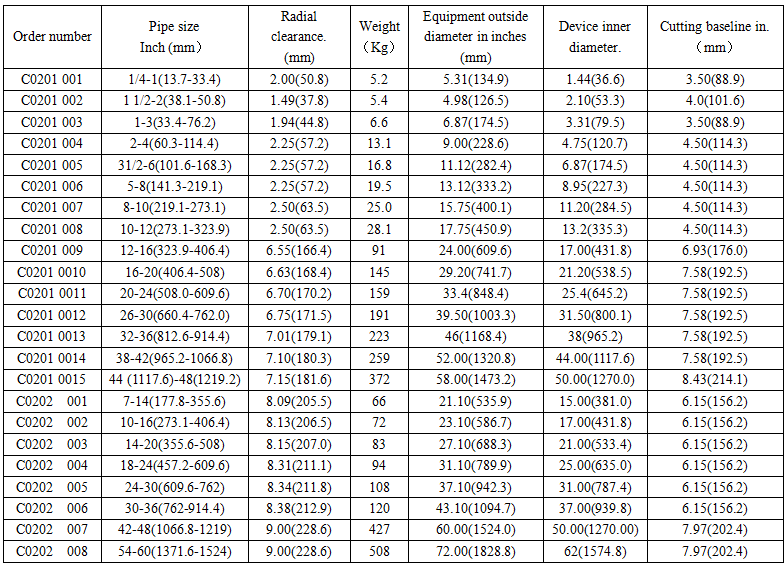

Specifications and parameters

●Support all the mounting accessories: the wild card groove machine to cutting groove of thin-walled

tube, pipeline in the processing process and no distortion.Can be used for the installation of small size

than the maximum groove machine 1 "pipe.Diameter tracking attachments: in processing "

is not round pipe, use outside diameter tracking attachments of the excircle tracking, adjusting the position

of the cutter, the cutting groove thickness.

●Auto feed stop accessories: equipped with spring pin of the automatic feed stop attachment cantravel in the

preset stop tool feed and to control the cutting tool of the cutting depth.

●Connecting hinge: connecting hinge is arranged at one end of the two parts of the flap type beveling machine, beveling machine into a whole, convenient installation and transportation.

●Reverse drive components: if the processing space is narrow, the reverse drive part is fixed on the front end of the motor beveling machine.

●Support back ring: the need for increasing groove machine stiffness and flexible installation, can be installed support ring back and increase the second fastening bolts can improve the beveling machine

installation load distribution and positioning control.Profile tracking attachments: the attachment for pipe op ening end complex groove. Copying with tracking attachments using single processing form.

According to preset groove shape tracking feed,takes the shape of the groove.

● Rolling cutter: - rolling cutter has become "non chip cutting knife,the use of sharp edges of the roller of the thin walled pipe cutting. Cutting wheel adopts the gradual cutting, replacing the

metal cutting tool with no chip cutting, which is an ideal choice to prevent the debris pollution.